Gas Fired Oven

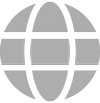

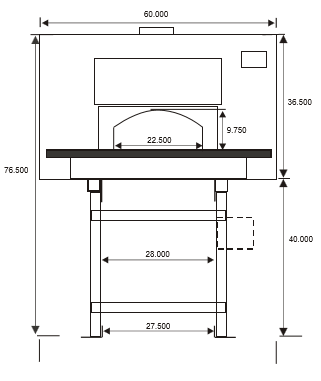

Exterior dimensions – 60” x 44”

Interior dimensions – 52” x 32” (Oval)

Oven entrance opening: 22 ½” – 9 ¾”

Clearance to combustible sidewalls: 1 inch

Weight: 3500 lb

Pizza Capacities:

- 12” Pizzas: 4-5 / 16” Pizzas: 2-3

Fuel Options:

- 90-Due’-PA – Wood Fired (No utilities required)

- 90-Due’-PAG – Gas Fired

- 90-Due’-PAGW – Gas/Wood Fired

Utilities Required:

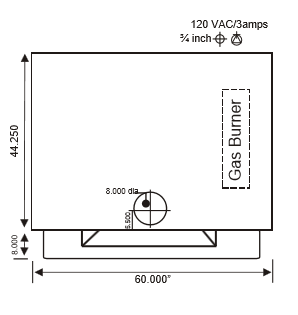

- 115,000 BTU – 7” W.C. – LP GAS 10” (for PAG and PAGW only)

- 3/4” female NPT Gas Inlet (for PAG and PAGW only)

- 120 VAC/ 3 AMP electrical connection

Utilities Required:

- 120VAC/ 3 AMP electrical connection

- 115,000 BTU Natural Gas or Propane (LP)

- Gas Inlet 3/4” female NPT (For PAG and PAGW only)

Total Weight 3,500 lbs

Fuel Type

Venting Requirements

Direct connection to a power ventilated ETL/UL listed

grease duct rated chimney or ETL/UL listed Type 1

exhaust hood.

Ovens come standard with:

- Factory finished black powder coat paint

- Digital thermometer controller

- Heavy duty gas burner system with ceramic fire logs

- Cast aluminum door with Teflon handles

- Granite shelf

- Hood cover (stainless or copper trim)

- Stainless steel pizza peel

- 5 year limited warranty on refractory

- 1 year limited warranty on gas / electrical

Downloads:

New York MEA No.: 207-98E